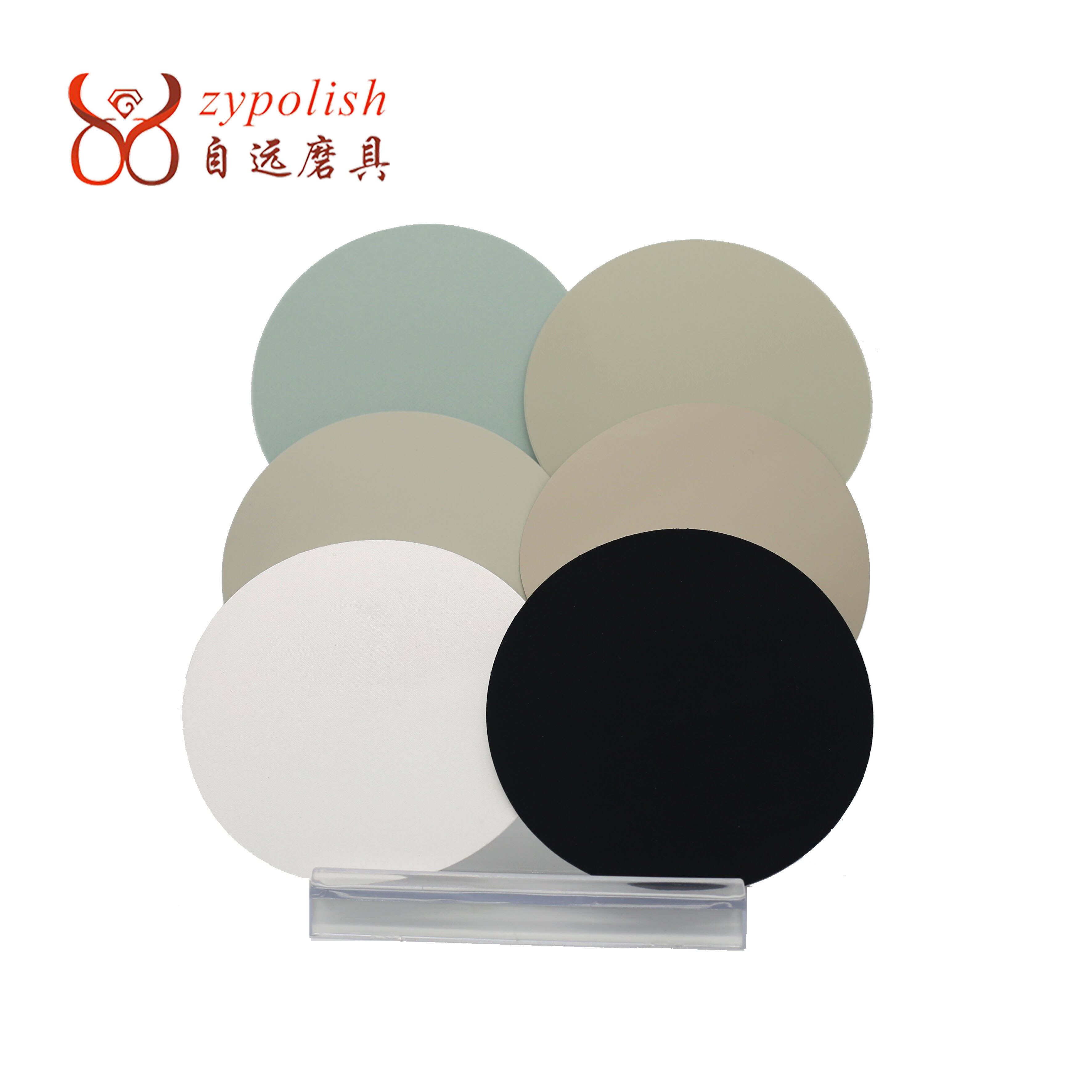

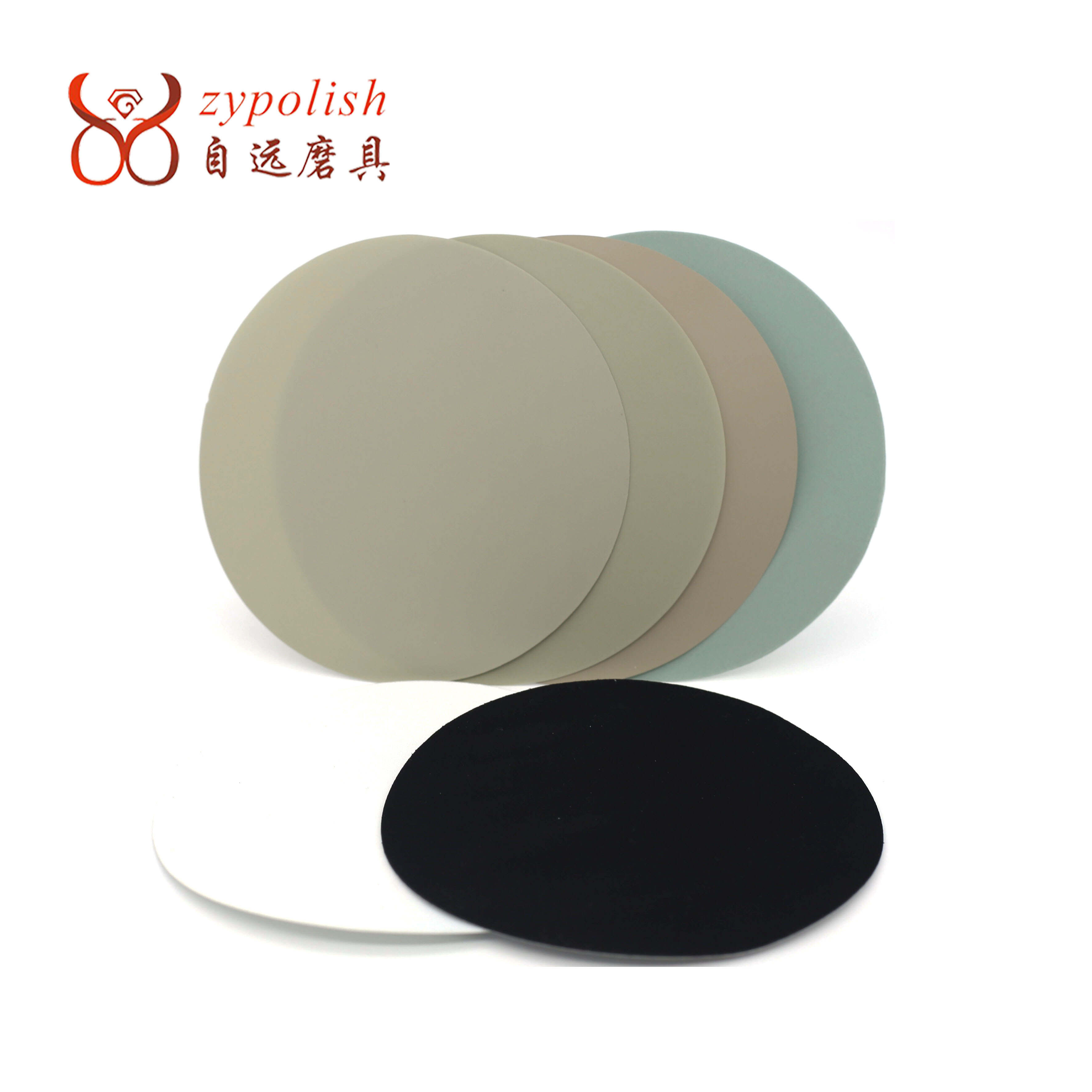

Product Features

Uniform Abrasive Distribution for Consistent Finishes

The film uses precision-coated silicon carbide particles that are evenly dispersed across the surface, delivering consistent cutting rates and uniform finishes throughout the polishing process.

Durable and Flexible Polyester Backing

Constructed with high-strength polyester film, the backing offers excellent tensile strength and flexibility, ensuring resistance to tearing and easy handling during high-speed polishing.

High-Precision Polishing Performance

Designed for fiber optic and micro-electronic polishing, it achieves exceptional surface accuracy critical for maintaining low-loss and high-efficiency optical connections.

Reliable Batch-to-Batch Stability

Strict quality control and manufacturing standards result in minimal variation between batches, ensuring stable performance and repeatable results across production cycles.

Compatible with Wet and Dry Polishing Methods

Suitable for use with water, oil, or dry environments, this film offers broad adaptability to various machine types and process requirements.

Product Parameters

|

Specification

|

Details

|

|

Product Name

|

Silicon Carbide Lapping Film

|

|

Abrasive Material

|

Silicon Carbide

|

|

Backing Material

|

High-Strength Polyester Film

|

|

Backing Thickness

|

3 mil

|

|

Product Form

|

Disc & Roll

|

|

Standard Sizes

|

127mm / 140mm × 150mm, 228mm × 280mm, 140mm × 20m (Customizable)

|

|

Micron Grade

|

Micron-grade and sub-micron

|

|

Application

|

Flat Lapping, Polishing, Superfinishing

|

|

Primary Usage

|

Fiber Optic Connectors (MPO, MT, MTP, MNC, Jumpers)

|

|

Substrates

|

Ceramic, Glass, Plastic, High-Hardness Metal, Silicon Carbide

|

Applications

Fiber Optic Industry

For end-face polishing of MT/MPO/MTP/MNC connectors and jumpers to achieve minimal insertion loss and high signal integrity.

Electronics and Display

Precision polishing of LEDs, LCD panels, and optical lenses requiring uniform surface textures.

Metallurgy and Mechanical Components

Used for finishing motor shafts, steering devices, and metal rollers where fine-tolerance surface quality is critical.

Semiconductor Industry

Applied to polish semiconducting materials for component fabrication and inspection readiness.

Data Storage Devices

Suitable for polishing magnetic heads and HDD surfaces requiring ultra-smooth contact interfaces.

Recommended Uses

Polishing MT, MPO, and MTP fiber optic connectors to improve signal transmission performance and minimize end-face defects.

Rough and fine grinding of ceramic ferrules in fiber jumpers to prepare for optical alignment and bonding.

Flat lapping of optical lenses and crystal substrates to ensure visual clarity and dimensional consistency.

Superfinishing of precision shafts and rollers in automation and machinery for smooth rotational performance.

Finishing semiconductor wafers and LED substrates prior to packaging or assembly.

Order Now

Boost your polishing productivity and product quality with our Silicon Carbide Polishing Film—a reliable, high-precision solution trusted across the fiber optic and electronics industries. Available in customizable sizes and multiple formats, it's perfect for both manual and automated polishing systems. Contact us today for factory-direct pricing, technical support, or to request a sample. Let us help optimize your polishing workflow with consistent results and long-term value.