Product Features

High Precision Polishing for Fiber Optic Connectors

Designed for polishing MT/MPO/MTP/MNC connectors, this film delivers repeatable surface flatness and ultra-smooth finishes to ensure excellent optical performance.

Uniform Abrasive Distribution for Consistent Results

Each sheet features evenly dispersed silicon carbide abrasives that ensure predictable material removal, reduced defect rates, and tight process control across batches.

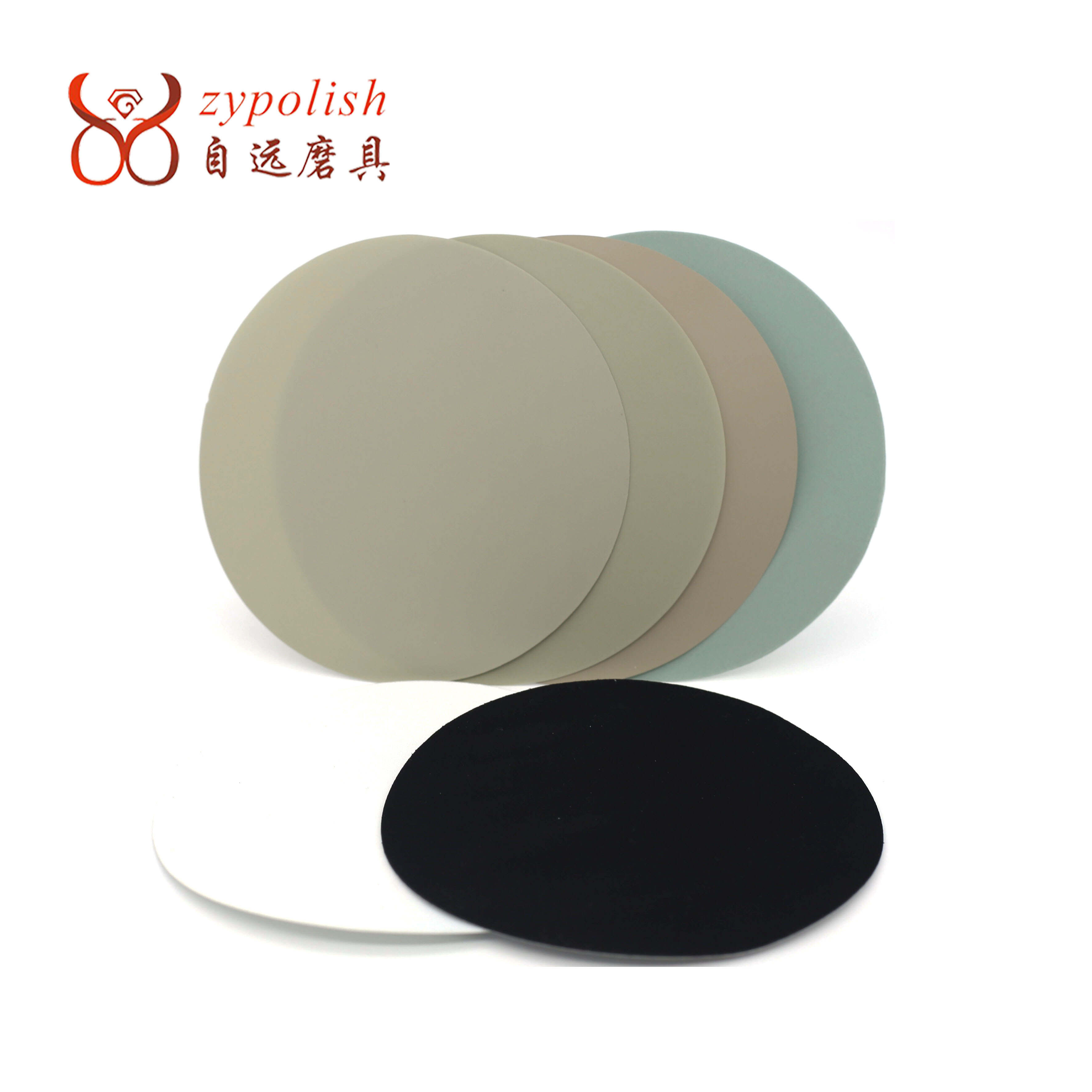

Flexible and Strong Polyester Backing

Built on a high-strength polyester film, the backing resists tearing while conforming well to different connector geometries for smooth, effective polishing.

Versatile Compatibility with Polishing Media

Suitable for dry, water-based, or oil-based polishing systems, the film integrates seamlessly into your existing fiber optic connector production lines.

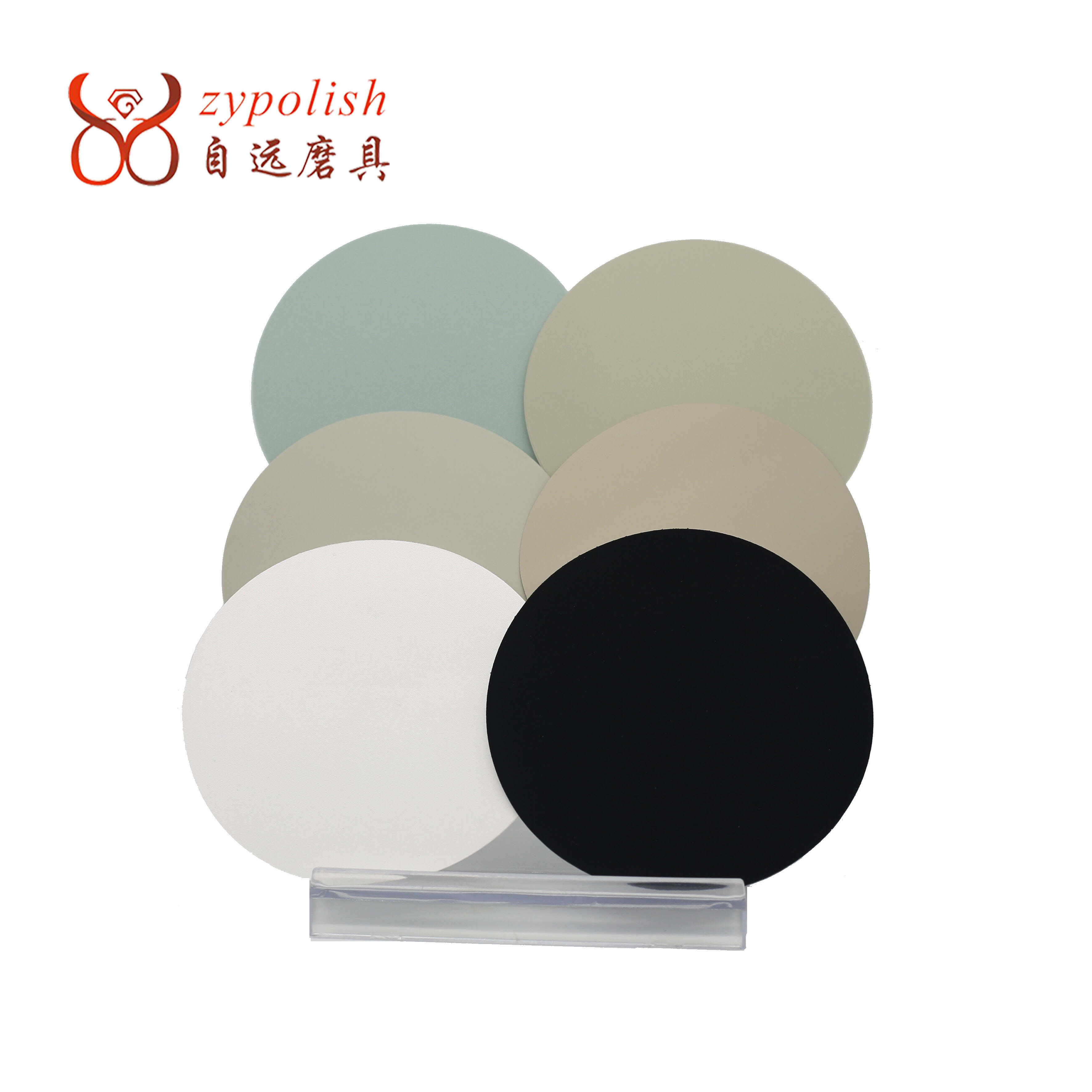

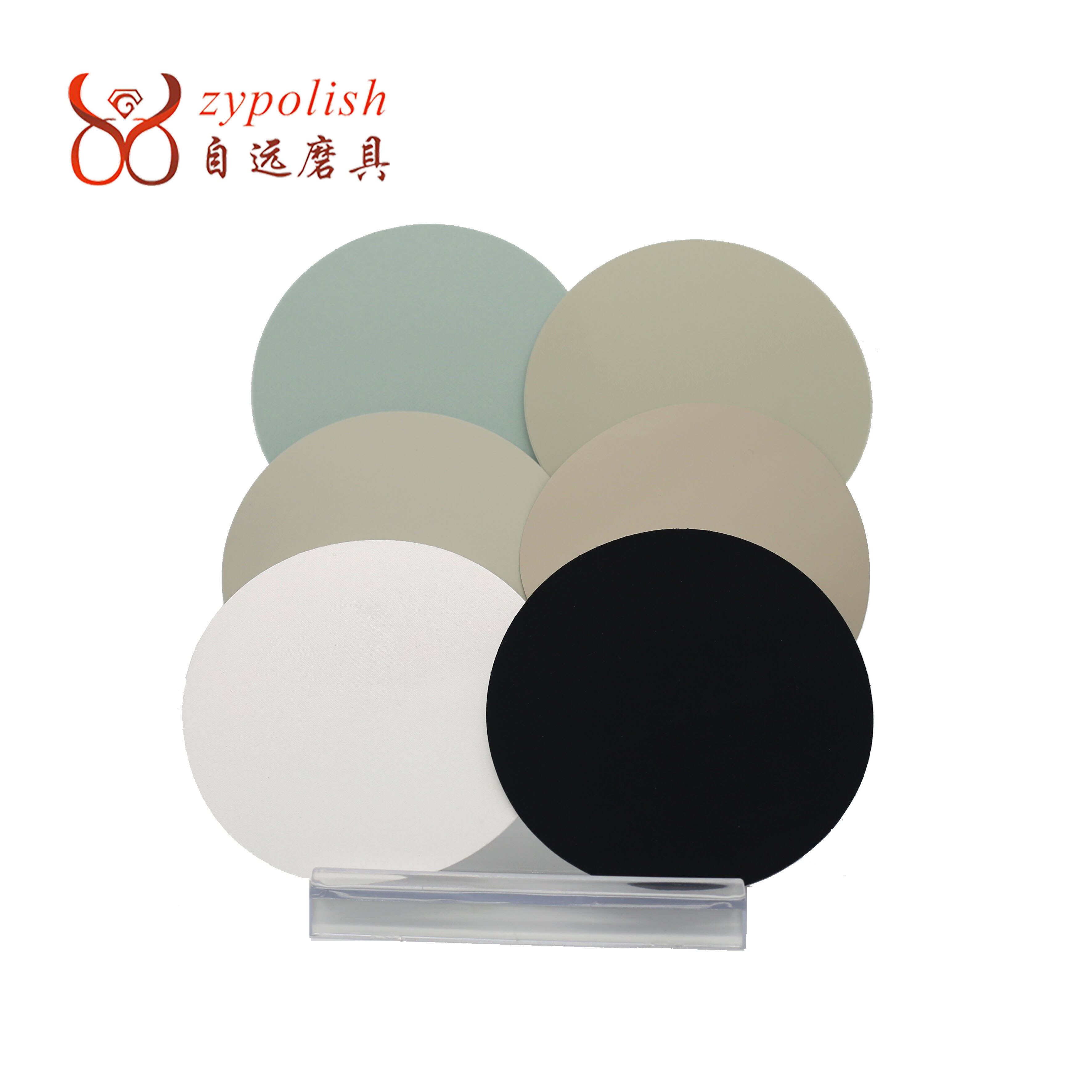

Available in Various Grit Sizes and Formats

Offered in multiple grit sizes and customizable formats (discs and rolls), the film is adaptable to various connector types, machine settings, and polishing stages.

Product Parameters

|

Parameter

|

Specification

|

|

Product Name

|

Silicon Carbide Lapping Film

|

|

Abrasive Material

|

Silicon Carbide

|

|

Backing Material

|

High-Strength Polyester Film

|

|

Backing Thickness

|

3 mil (75µm)

|

|

Available Formats

|

Disc & Roll

|

|

Standard Sizes

|

127mm / 140mm × 150mm / 228mm × 280mm / 140mm × 20m (customizable)

|

|

Suitable Connectors

|

MT, MPO, MTP, JUMPER, MNC

|

|

Substrate Compatibility

|

Ceramic, Glass, Metal, Plastic, Silicon Carbide

|

|

Polishing Method

|

Dry, Water, or Oil-Based

|

Applications

Fiber Optic Industry: For flat lapping and polishing of MT, MPO, and MTP connectors to ensure low insertion loss and high return loss.

Optics Manufacturing: Used for polishing optical lenses, crystals, LEDs, and LCD displays requiring high surface quality.

Industrial Components: Suitable for polishing motor shafts, steering components, hard metal rollers, magnetic heads, and HDD surfaces.

Semiconductor & Electronics: Ideal for polishing hard substrates including ceramics, silicon carbide, and high-hardness metals in microelectronics.

Recommended Uses

Perfect for cutting angle and end-face polishing of MPO and MTP fiber optic jumpers, ensuring high optical transmission performance.

Ideal for fine grinding and surface preparation of ceramic ferrules, used in high-speed fiber optic connectors and adapters.

Recommended for precision polishing of LED and LCD panel components, where surface smoothness and defect minimization are critical.

Suitable for restoring and finishing metal rollers and motor shafts, improving surface quality and extending component lifespan.

Effective in superfinishing of high-hardness materials such as tungsten carbide and silicon carbide, commonly found in semiconductor manufacturing.

Order Now

Our silicon carbide lapping film is designed for fiber optic polishing, offering accuracy, repeatability, and durability. Suitable for optical connectors, electronics, and mechanical parts. Contact us to order, request free samples, or discuss custom formats and grit sizes.