Product Features

Uniform Abrasive Particle Dispersion for Consistent Results

Each polishing film is manufactured using a proprietary dispersion technique that ensures uniform abrasive particle distribution, enabling smooth, scratch-free finishes and reducing the risk of uneven polishing.

High Strength and Flexibility for Complex Surfaces

Engineered with enhanced material integrity, the films maintain optimal strength while offering the flexibility to adapt to curved and irregular surfaces, making them suitable for a wide range of polishing tasks.

Superior Polishing Accuracy for High-Precision Applications

Designed for fine polishing, the diamond films deliver high dimensional accuracy and tight tolerance finishes, critical for components such as fiber optic connectors, optical lenses, and semiconducting materials.

Stable Batch-to-Batch Quality Control

Our rigorous production process ensures low variance between batches, offering stable performance and minimizing rework or inconsistency in industrial operations.

Versatile Use with Dry, Water, or Oil-Based Polishing Methods

The films are compatible with dry polishing as well as with water or oil lubricants, allowing users to select the method best suited to their application and material.

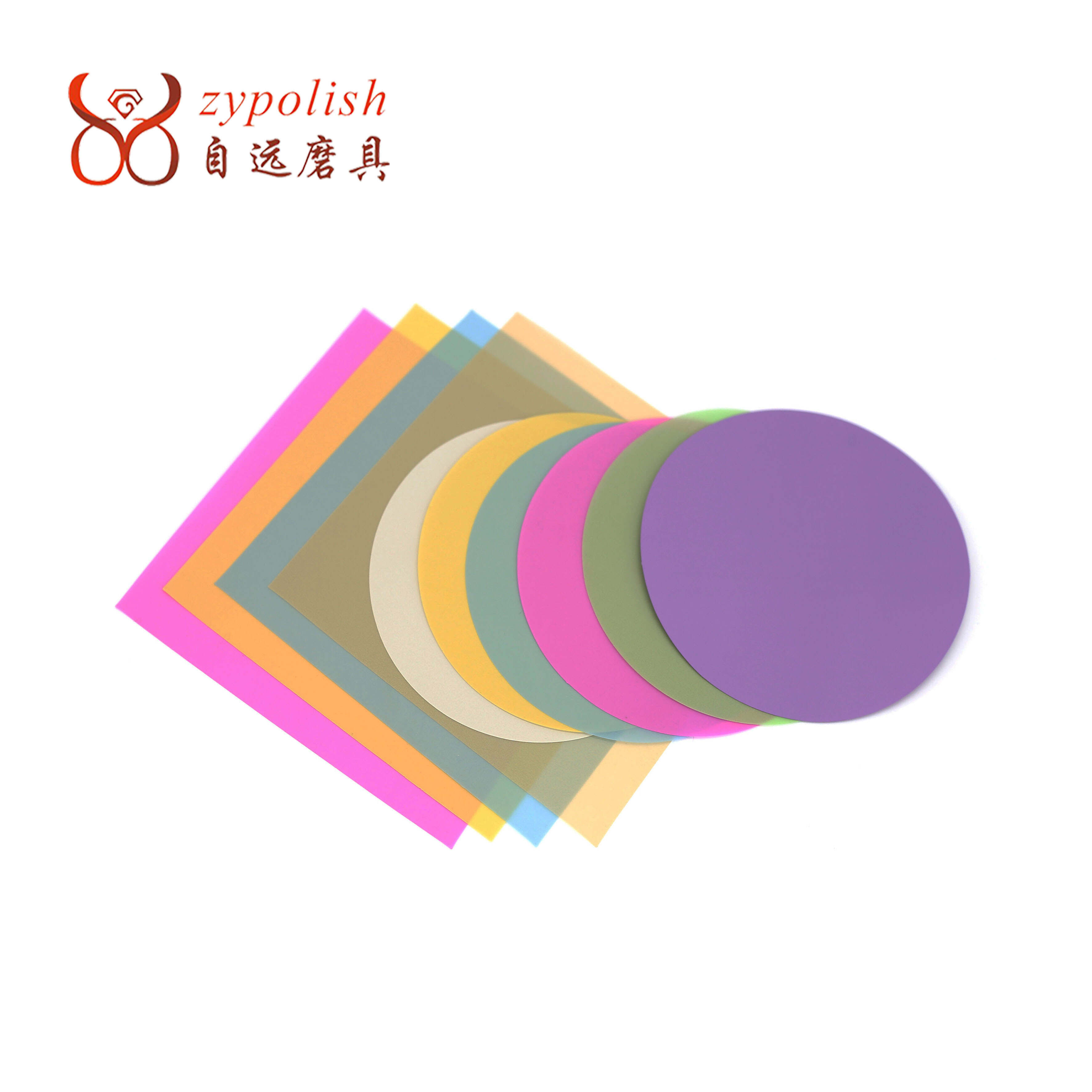

Product Parameters

|

Parameter

|

Details

|

|

Grit Options

|

30µm / 9µm / 3µm / 1µm / 0.5µm / 0.05µm

|

|

Disc Diameters

|

Φ127mm (5 inch), Φ203mm (8 inch), etc.

|

|

Sheet Sizes

|

114mm × 114mm, 152mm × 152mm (6 inch), etc.

|

|

Film Thickness

|

75 micron

|

Applications

Fiber Optics Industry: Cutting and polishing of fiber optic connector end faces for improved transmission quality.

Optics Manufacturing: Finishing of optical lenses, crystals, LEDs, and LCDs to achieve ultra-smooth surfaces.

Precision Engineering: Polishing of motor shafts, steering components, and metal rollers.

Electronics Industry: Used in the finishing of HDD components, magnetic heads, and semiconducting materials.

R&D and Laboratory Testing: Ideal for precision material research and development environments.

Recommended Uses

Perfect for preparing the cutting angle of fiber optic connectors, ensuring optimal signal transmission and minimal reflection loss.

Ideal for rough to fine grinding of semiconducting wafers, where surface flatness and scratch control are essential.

Reliable for polishing of metal rollers and shafts used in industrial machinery to enhance performance and durability.

Effective in grinding and polishing LCD/LED screens and optical lenses, where clarity and uniformity are critical.

Suitable for refinishing hard drive components and magnetic heads to maintain device performance and longevity.

Order Now

Enhance your manufacturing and polishing processes with our high-performance diamond polishing film discs. We offer a wide selection of grits and sizes to meet diverse industrial needs. Contact us today to request samples, discuss bulk pricing, or customize specifications for your application.